- Mon-Fri 9am-5pm

- hello@innodez.com

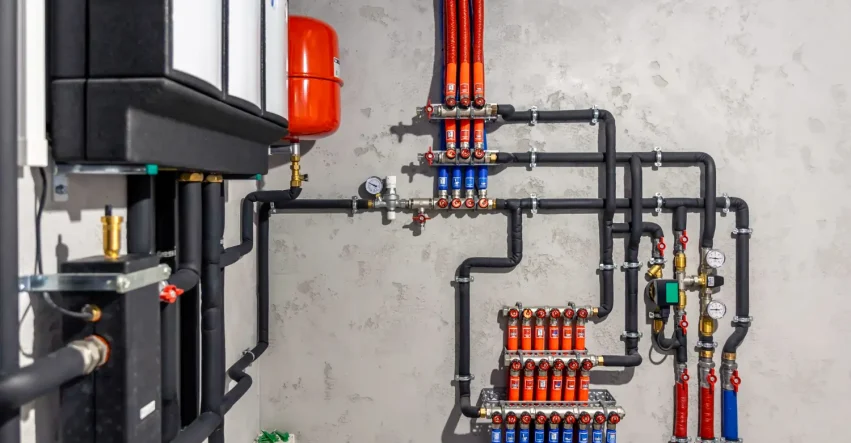

Mechanical, Electrical, and Plumbing (MEP) design is critical to the success of any building project. At InnoDez, we understand that even seasoned engineers and architects can encounter common pitfalls that lead to costly delays, compliance issues, and increased expenses. This blog explores frequent MEP design mistakes and offers expert tips from InnoDez on how to avoid them, ensuring your projects run smoothly and meet all necessary standards.

Effective MEP design doesn’t just meet immediate needs; it improves building efficiency, occupant comfort, and long-term operational savings. Recognizing common errors and adopting best practices is essential for developers, builders, and consultants who want reliable results.

Moreover, with the growing focus on sustainability and smart technologies in building design, MEP systems now play a central role in reducing environmental impact. Improving system integration early in design phases can yield significant benefits in energy consumption, cost savings, and occupant wellbeing.

Integrating mechanical, electrical, and plumbing systems involves complex coordination. Here are the most frequent mistakes InnoDez encounters in our projects:

Additionally, many projects miss opportunities by not integrating smart controls, sensors, and automation—key elements InnoDez includes to enhance system performance and flexibility.

Another less obvious mistake is failing to properly assess the impacts of newer building materials or architectural designs on MEP systems. For example, highly insulated or airtight buildings may require more precise HVAC balancing and ventilation designs to maintain indoor air quality. Such oversights can result in occupant discomfort or increased energy use post-construction.

InnoDez recommends a structured, collaborative approach supported by advanced tools and expertise to avoid costly errors:

1. Embrace Holistic Coordination: Conduct frequent design coordination meetings among all stakeholders. Utilize Building Information Modeling (BIM) to detect clashes early and improve integration, reducing on-site surprises and delays.

2. Engage Local Code Specialists Early: Ensure compliance with local regulations such as the National Construction Code (NCC). InnoDez’s specialists keep projects aligned with code updates, preventing compliance issues.

3. Conduct Precise Load and System Sizing Calculations: Use detailed, site-specific data rather than generic templates. InnoDez’s engineers rigorously validate system capacities tailored to building demands.

4. Maintain Thorough, Updated Documentation: Keep all design documents clear, current, and accessible via cloud-based platforms.

5. Design With Future Expansion in Mind: Plan for anticipated growth and technological advances by providing spare capacity and infrastructure flexibility.

6. Prioritize Energy-Efficient Solutions: Integrate energy modeling early and specify high-efficiency systems and smart controls.

7. Plan Adequate Space for Maintenance and Access: Design equipment areas with safe, straightforward maintenance access, consulting operations teams to validate needs.

Furthermore, InnoDez supports the integration of modular MEP systems, which allow faster installation, improved quality, and reduced onsite risks—an increasingly popular solution for complex projects.

One Melbourne commercial tower faced significant delays from clashes between HVAC ductwork and electrical conduits due to insufficient coordination and no early BIM implementation. After adopting weekly multidisciplinary BIM meetings, the project’s issues diminished, and it met its original completion timeline.

Another residential development was held up when fire safety regulatory updates were missed, leading to costly ventilation redesigns. Early involvement of compliance specialists could have prevented the setbacks.

These cases highlight why InnoDez prioritizes collaboration, technology adoption, and stringent regulatory compliance throughout all projects.

InnoDez also encountered projects where lack of design flexibility caused expensive retrofits within just a few years. Factoring in facility management feedback into the design phase helped remedy this pattern by enabling scalable systems on later jobs, a practice now standard at InnoDez.

Modular MEP systems—where components are prefabricated offsite in controlled environments—offer significant benefits increasingly leveraged by InnoDez, including:

Integrating modular systems requires thoughtful upfront planning but InnoDez experience shows the long-term advantages far outweigh initial complexity. They also help avoid common design pitfalls by streamlining coordination and prefabrication.

Modular MEP approaches also align well with sustainable construction goals by reducing material waste and enabling easier integration of energy-efficient systems.

Avoiding MEP design mistakes is critical to on-time, on-budget delivery and ensuring safe, efficient buildings. InnoDez emphasizes integrated planning, stringent regulatory compliance, future-focused design, and innovative technologies like BIM and modular systems to achieve superior project outcomes.

For expert assistance on your next project, contact InnoDez to learn how our specialized MEP Engineering Services can help reduce risks and optimize results.

For further guidance on meeting building regulations and improving coordination, it’s essential to consult authoritative sources like the National Construction Code (NCC) Australia and follow global best practices such as those promoted by BuildingSMART International for BIM standards. These resources help ensure your MEP designs stay up-to-date, compliant, and efficient throughout the project lifecycle.